Anti-corrosive Sucker Rod Pump

Any question about our OCTG casting, please email sales@shengjipetro.com. You will get reply within 24 hours!

Key Features

- Anti-wear

- Anti-corrosion

- Chrome plated and nickel-phosphor plated

- For nickel-phosphor plating, we can do ID, OD and thread for brass barrel.

Anti-corrosive Brass Sucker rod pump

Do you still worry about the corrosion and wearing issue for sucker rod pump? Shengji has just what you’re looking for. Shengji is a professional Oil Field Brass Sucker rod pump manufacturer in China. With more than 50 years of historical precipitation, Shengji can manufacture reliable quality and stable performance Brass Sucker rod pump for various customers.

Shengji brass sucker rod pump can cover the nominal diameter from 1 1/16”-4 3/4”, the max. length can reach 34ft (10.4m). The plating layer hardness can reach 900HV100-1160HV100. With advanced technical support, we can carry out chrome plated and nickel-phosphor plated for brass sucker rod pump barrel ID.

Every brass sucker rod pump is manufactured with stable quality and good performance. Shengji is a brand you can count on to provide the best-quality brass sucker rod pump .

| Type | Thick wall rod pump | Thin wall rod pump | Tubing pump | |

| Bore size (in) | 1 1/16~2 1/4 | 1 1/4~2 1/2 | 1 3/4~3 3/4 | |

| Plunger length (ft) | 2-24 | |||

| Barrel length (ft) | 2-34 | |||

| Material | Barrel | A4: Chrome plate on Ni/Cu alloy

A5: Chrome plate on brass B4: Heavy chrome plate on Ni/Cu alloy B5: Heavy chrome plate on brass |

||

| Plunger | D1-D3: Spray metal with Ni/Cu alloy ends

E1-E3: Spray metal with Nickel plated pin ends and entire length of inside diameter F1-F3: Spray metal with Nickel plated pin ends and entire length of inside diameter |

|||

| Corrosion medium | H2S, CO2, Saline water, Oxygen | |||

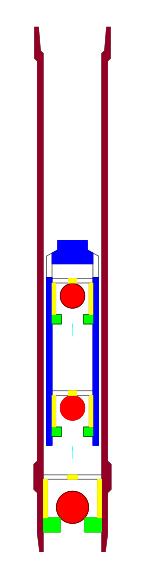

In order to increase the anti-corrosive property of tubing pump, Shengji designed anti-corrosive tubing pump. The conventional tubing pumps usually use carbon steel as the basic material in the high corrosion oil well. Such pumps easily get corroded and the service life is greatly reduced.

Compared with conventional tubing pump, anti-corrosive pump adopts a special technology and has a strong anti-corrosive property. In this pump, the barrel has an anti-corrosive treatment; the surface of the plunger coated with nickel alloy and the cage made of anti-corrosive material with good mechanical property.

This completely solves the corrosion and crack problems. The ball and seat have strong anti-corrosive and wear resistance properties. With these good properties, this pump can be used in the medium with high H2S, CO2 and salinity. It guarantees an extended service life and good performance.

- Uses a special anti-corrosive material that has long service life.

- Take anti-corrosive treatment.

- Good wear resistance property.

- Suitable for high salinity oil well.

| Model | Nominal Diameter (in) | Stroke length

(ft) |

Connect tubing

(in) |

Connect sucker rod

(in) |

Pump constant (K) | Max diameter (mm) |

| 25-150THFF | 1 1/2 | 6-30 | 2 7/8 | 3/4 | 1.642 | 3 1/2 |

| 25-175THFF | 1 3/4 | 2.235 | ||||

| 25-200THFF | 2 | 2.919 | ||||

| 25-225THFF | 2 1/4 | 3.694 | ||||

| 30-250THFF | 2 1/2 | 3 1/2 | 7/8 | 4.56 | 4 1/4 | |

| 30-275THFF | 2 3/4 | 5.518 | ||||

| 30-325THFF | 3 1/4 | 7.707 | 4 1/2 | |||

| 30-375THFF | 3 3/4 | 1 | 10.261 | 4 5/8 |

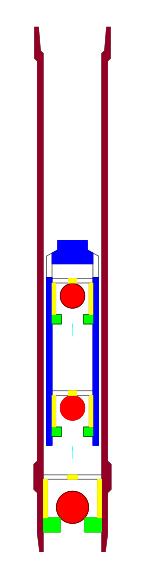

Shengji developed a new cage lined anti-corrosive pump. Compared to other anti-corrosive pumps, this pump takes more treatment to the cage and it adds a hardliner in the valve chamber. The plunger upper cage and lower cage take the nickel-phosphor plate.

Although this increase the cost, but it guarantees good anti-corrosion and better mechanical performance. The standing valve cage uses a Teflon liner. This materials has a very good anti-corrosion property, wear resistance and heat resistance quality. It is superior to other companies’ liner material.

These material improves wear resistance of the cage, enhanced anti-corrosion property, and extend the cage life. The travelling ball material is tungsten carbide, it has improved hardness and impact resistance, the ball and seat have a perfect seal.

- The pump has a hard liner which increase anti-corrosive property.

- Use nickel-phosphor plate for plunger cage.

- Long service life in the corrosion well.

- It is suitable for the high salinity well.

| Model | Nominal Diameter (in) | Stroke length

(ft) |

Connect tubing

(in) |

Connect sucker rod

(in) |

Pump constant (K) | Max diameter (mm) |

| 25-150THCF | 1 1/2 | 6-30 | 2 7/8 | 3/4 | 1.642 | 3 1/2 |

| 25-175THCF | 1 3/4 | 2.235 | ||||

| 25-200THCF | 2 | 2.919 | ||||

| 25-225THCF | 2 1/4 | 3.694 | ||||

| 30-250THCF | 2 1/2 | 3 1/2 | 7/8 | 4.56 | 4 1/4 | |

| 30-275THCF | 2 3/4 | 5.518 | ||||

| 30-325THCF | 3 1/4 | 7.707 | 4 1/2 | |||

| 30-375THCF | 3 3/4 | 1 | 10.261 | 4 5/8 |

For the high production and high H2S, CO2 oil wells, Shengji designed and manufactured an integral match anti-corrosive pump. In this pump, the barrel is made of stainless material and make chrome plated, the fitting is made of austenitic stainless steel, the ball and seating is a tungsten carbide which increases the pump anti-corrosive property.

This kind pump matches drainer device, puller device and pump as an integral unit. It has a strong anti-corrosive property. This pump solves the complement problems of the tools and fluid corrosion problems. So, it is suitable for the high production well, which has sufficient feed fluid and need large bore pump to increase oil production.

The super anti-corrosive pump has a good performance in the high H2S, CO2 oil well, extend the service lift and reduce the cost of oil production.

- Super anti-corrosive property

- Increase oil production in the corrosion well.

- Uses drainer, puller and pump as an integral unit.

- Solve the complement problems of tools.

| Model | Nominal Diameter (in) | Stroke length

(ft) |

Connect tubing

(in) |

Connect sucker rod

(in) |

Pump constant (K) | Max diameter (mm) |

| 25-225THZTF | 2 1/4 | 6-30 | 2 7/8 | 3/4 | 3.694 | 3 5/8 |

| 30-275THZTF

30-275THZTF II |

2 3/4 | 3 1/2 | 7/8 | 5.518 | 4 1/4 | |

| 30-325THZTF

30-325THZTF II |

3 1/4 | 3 1/2 | 7/8 | 7.707 | 4 1/2 | |

| 30-375THZTF

30-375THZTF II |

3 3/4 | 3 1/2 | 1 | 10.261 | 4 5/8 |